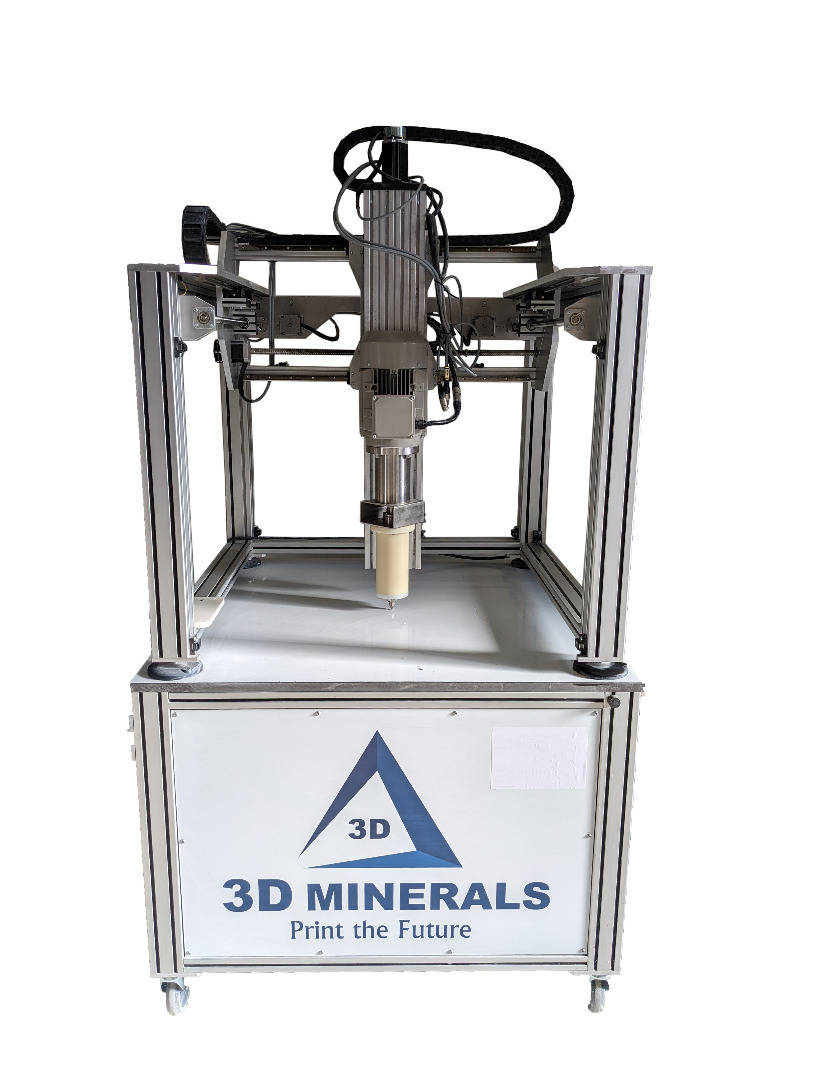

Cartesian 3D printer : Pure versatility

Cartesian 3D printer with S.D.M. or P.D.M. technologies

This 3D printer is perfect for studies and demonstrations. Manufactured with custom dimensions, this fully enclosed 3D printer allows the production of ceramic parts with different technologies:

- Robocasting: Driving of Nema 17, 23 and 34 motors and/or three-phased or Brushless motors, with the cartridge being placed as close as possible to the extruder in order to limit pressure losses (extrusion output up to approximately 6mm)

- S.D.M.: Transformation of the ceramic slurry into a paste in the mixing body by means of two feed pumps for the slurry and the additive (extrusion nozzle up to 25 mm)

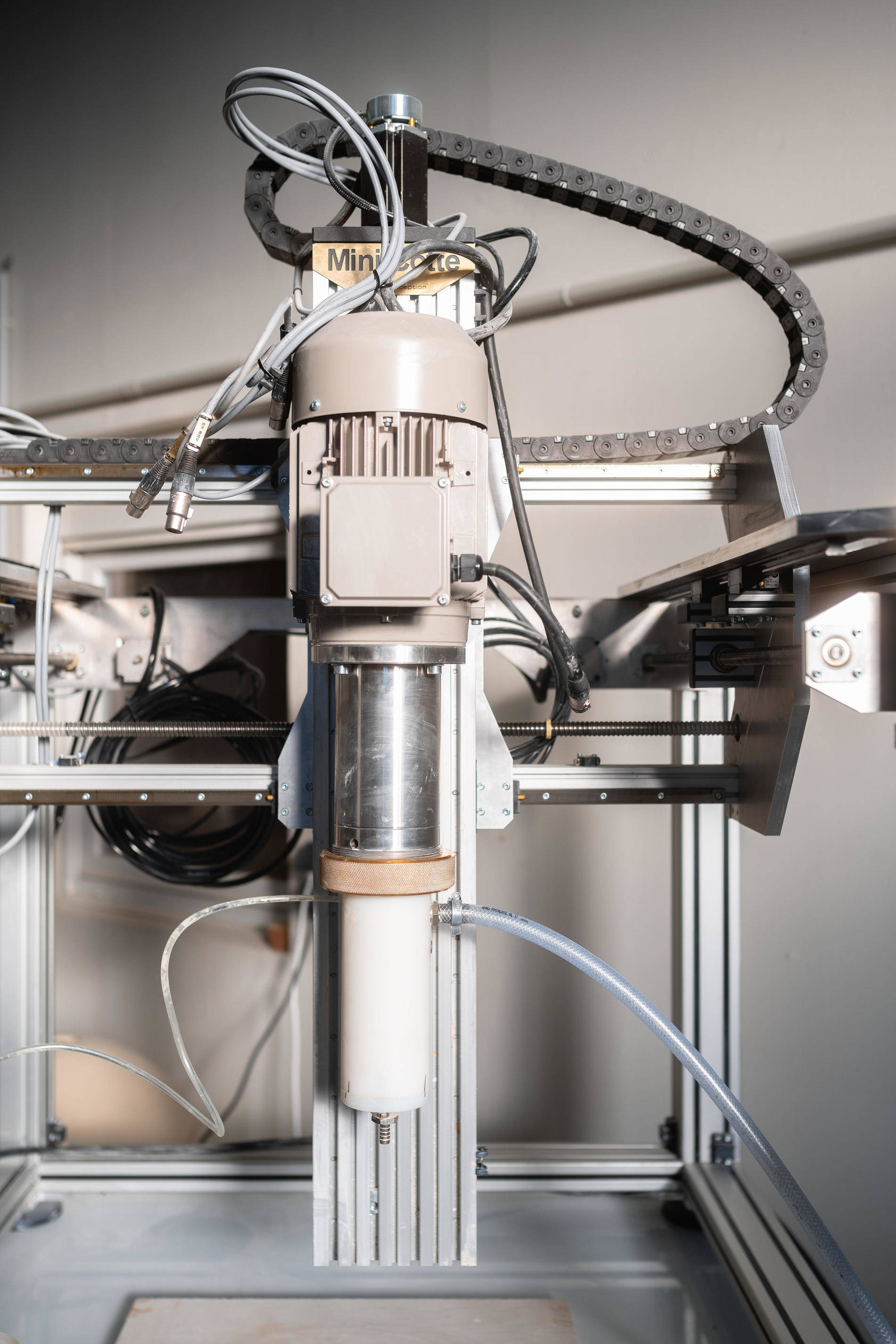

Feeding patented S.D.M. (Slurry. Deposition. Modeling) technology

Mixer/Extruder body

This 3D printer is perfect for studies and demonstrations. Manufactured with custom dimensions, this fully enclosed 3D printer allows the production of ceramic parts with different technologies:

- Robocasting: Driving of Nema 17, 23 and 34 motors and/or three-phased or Brushless motors, with the cartridge being placed as close as possible to the extruder in order to limit pressure losses (extrusion output up to approximately 6mm)

- S.D.M.: Transformation of the ceramic slurry into a paste in the mixing body by means of two feed pumps for the slurry and the additive (extrusion nozzle up to 25 mm)

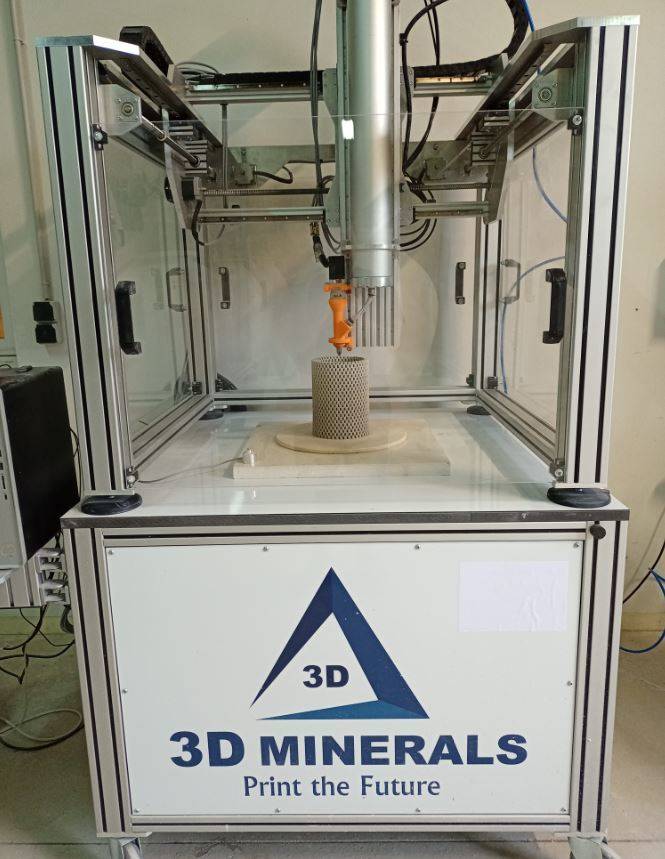

Feeding by means of a cartridge on board the machine

This 3D printer is perfect for studies and demonstrations. Manufactured with custom dimensions, this fully enclosed 3D printer allows the production of ceramic parts with different technologies:

- Robocasting: Driving of Nema 17, 23 and 34 motors and/or three-phased or Brushless motors, with the cartridge being placed as close as possible to the extruder in order to limit pressure losses (extrusion output up to approximately 6mm)

- S.D.M.: Transformation of the ceramic slurry into a paste in the mixing body by means of two feed pumps for the slurry and the additive (extrusion nozzle up to 25 mm)

Feeding patented S.D.M. (Slurry. Deposition. Modeling) technology

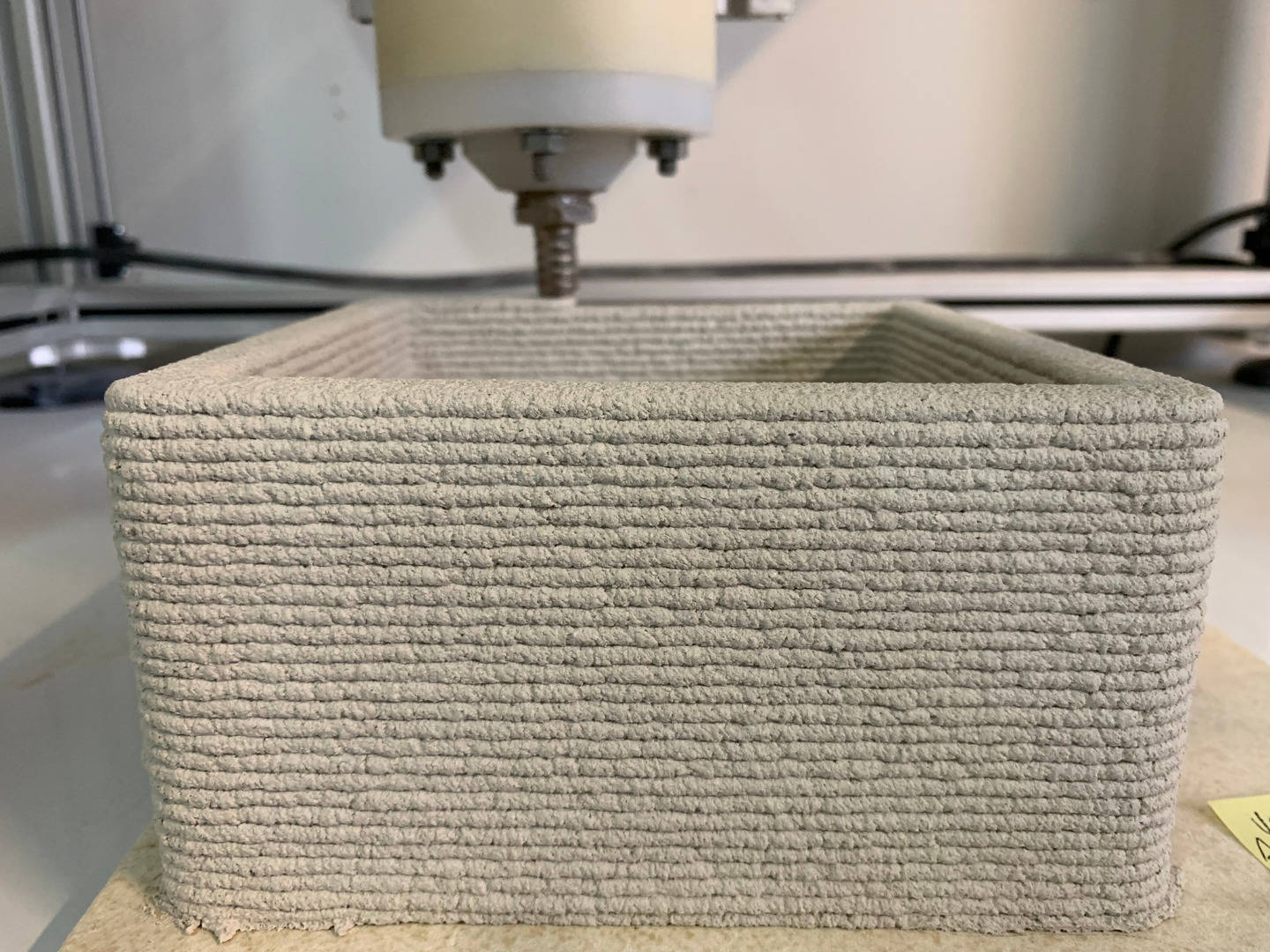

This 3D printer is perfect for studies and demonstrations. Manufactured with custom dimensions, this fully enclosed 3D printer allows the production of ceramic parts with different technologies:

- Robocasting: Driving of Nema 17, 23 and 34 motors and/or three-phased or Brushless motors, with the cartridge being placed as close as possible to the extruder in order to limit pressure losses (extrusion output up to approximately 6mm)

- S.D.M.: Transformation of the ceramic slurry into a paste in the mixing body by means of two feed pumps for the slurry and the additive (extrusion nozzle up to 25 mm)

Feeding patented S.D.M. (Slurry. Deposition. Modeling) technology

This 3D printer is perfect for studies and demonstrations. Manufactured with custom dimensions, this fully enclosed 3D printer allows the production of ceramic parts with different technologies:

- Robocasting: Driving of Nema 17, 23 and 34 motors and/or three-phased or Brushless motors, with the cartridge being placed as close as possible to the extruder in order to limit pressure losses (extrusion output up to approximately 6mm)

- S.D.M.: Transformation of the ceramic slurry into a paste in the mixing body by means of two feed pumps for the slurry and the additive (extrusion nozzle up to 25 mm)